In Place Maintenance and Improved Reliability of Sludge Pumps – Hunterdon County WWTP

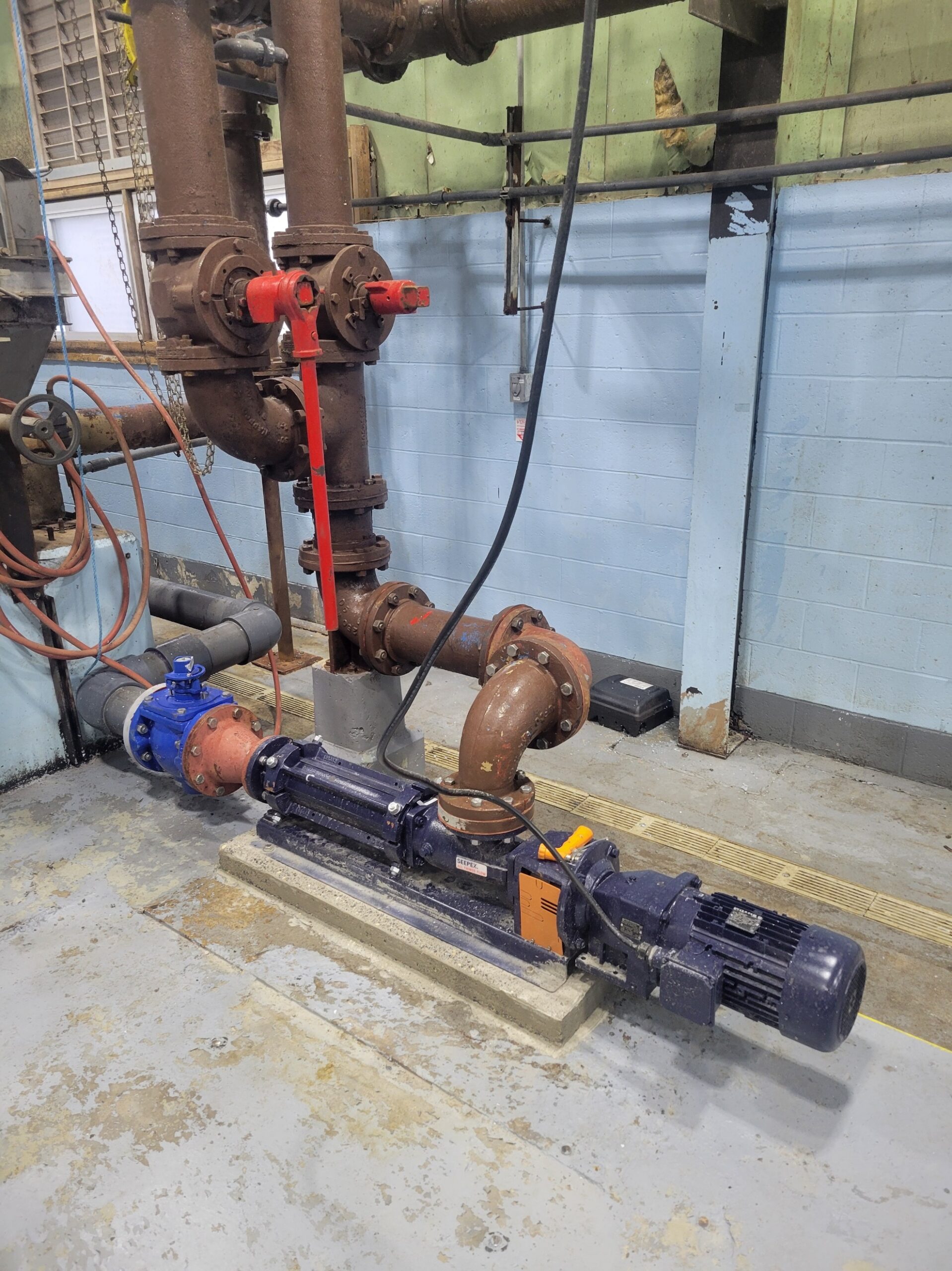

Existing thickened sludge pumps consistently caused issues with regards to maintenance, up time, and housekeeping. Often large amounts of sludge would end up around the unit creating a hazardous area for safety and maintenance. When issues occurred, it was difficult to repair the pump in a short timeframe.

By retrofitting a Seepex progressive cavity pump complete with the split stator SCT design, this allowed for the immediate improved performance. Easy access to the rotating components provides in place maintenance for any issues should they occur, and an enclosed design allows for reduced sludge in the surrounding areas.

“We have now installed multiple Seepex pumps throughout our sludge process. We cannot say enough how they have improved our sludge process reliability and maintenance practices, especially with the split stator design. Performance of these pumps is outstanding and we plan on continuing to retrofit our legacy sludge pumps moving forward.”

Cloacina: Pursuit of Excellence

https://www.cloacina.com/pursuit-of-excellence